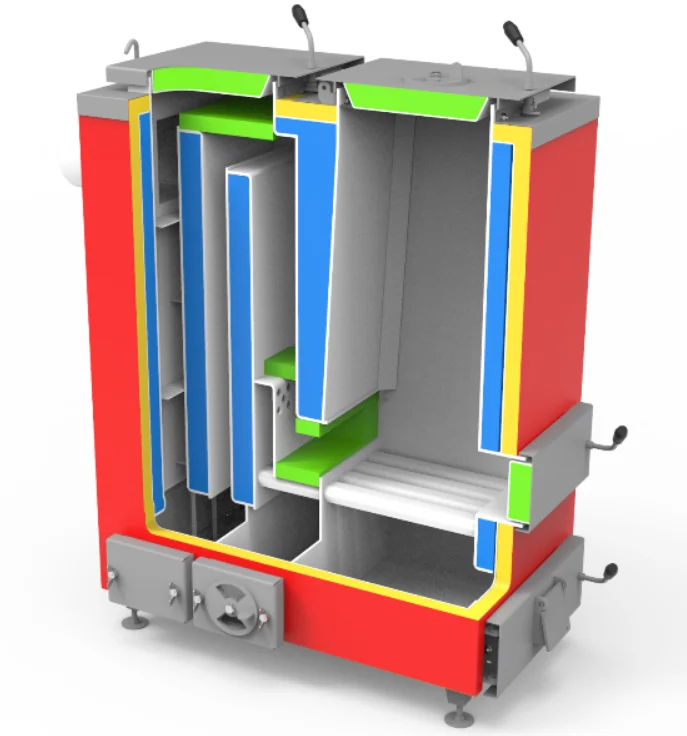

UKD DESIGN coal boilers are intended for supplying water central heating systems and preparing domestic hot water (DHW) through a buffer in the form of a hot water CO tank. The boiler drum is a welded structure made of one hundred percent steel sheets. The internal jackets (elements in contact with fire) are made of P265GH boiler steel sheet, 6 mm or 8 mm thick (for boilers with a capacity of more than 75 kW). For an additional fee FHUP

BRASTAL manufactures low-power boilers made of 8 mm thick sheet metal and boilers with a capacity of over 75 kW made of 10 mm sheet metal. The outer body of the water jacket of low-power boilers is made of 4 mm thick steel sheet. In the case of boilers with a capacity of more than 75 kW, it is a steel sheet 5 mm thick. The structure is additionally reinforced with struts.

The body is divided into three parts:

The body is divided into three parts:

- ashpan,

- furnace chamber,

- convection exchanger.

UKD DESIGN heating boilers are equipped with a mechanical air draft regulation in the form of a draft regulator and two manually adjustable secondary air draft openings.

The energy generated during the combustion process, in the form of high temperature, is transferred through the heat exchanger to the water with which the boiler is filled. The flue gas, which is transferred through the exchanger and the flue to the chimney, is a by-product of the process of generating thermal energy.

The air draft regulator automatically raises the air dosing flap when the water temperature in the boiler decreases in relation to the temperature set on the device, and closes the flap when the temperature rises to the set temperature.

The flue gases produced during the combustion process are discharged through the flue located in the rear, upper part of the boiler. There is an exhaust gas flap with tilt adjustment in the flue. The task of the throttle is to enable the customer to regulate the chimney draft, which affects the speed of combustion.

In order to reduce heat losses, the entire body of the boiler is packed with an external casing made of ready-made anti-corrosive sheets. The space between the outer casing and the water jacket is tightly filled with thermal insulation made of asbestos-free mineral wool. Additionally, the UKD DESIGN boiler has door covers that limit the heat flow to the environment.

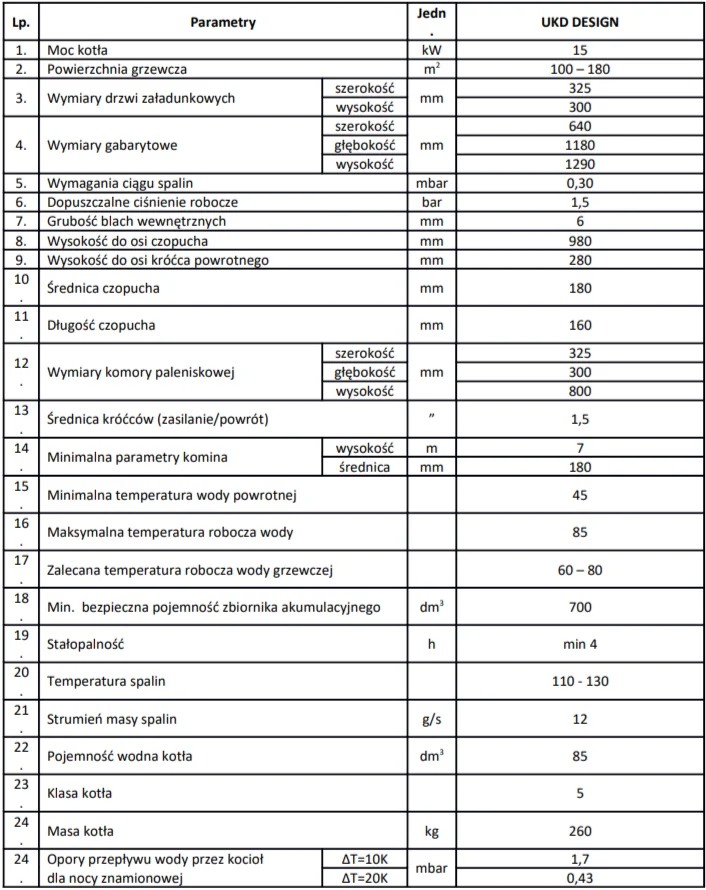

Dimensions and parameters of the UKD DESIGN boiler

UKD DESIGN stove - certificates and certificates

Our company's priority is to provide customers with the highest quality solutions. The CO boilers produced by us are always certified and are characterized by the highest technical parameters. BRASTAL central heating boilers have declarations of conformity, confirming compliance with national and European standards, including very strict ecological standards - thus reducing fuel consumption and reducing emissions of harmful substances.

The evidence of high quality are numerous certificates, e.g. of the Institute for Chemical Processing of Coal in Zabrze or the Institute of Power Engineering in Łódź (research laboratory for boilers and heating devices). The scope of obtained thermal and emission parameters of UKD Design 15 and UKD Design 25 boilers meet the requirements of class 5 contained in the PN-EN 303-5: 2012 standard.