Central heating furnaces and boilersWe have been producing CO boilers for over 25 years!

CO boilers are our passion. We manufacture CO boilers and provide high quality products. Our goal is to constantly improve our production techniques.

All our boilers are tested in the factory laboratory, are certified by the Institute for Chemical Processing of Coal in Zabrze and are CE marked. They also have an Environmental Friendly Device certificate issued by the Institute of Power Engineering, Research Institute, Department of Energy Equipment Research CUE in Łódź.

All boilers are made of high-quality P256GH steel sheet, 6-8 mm thick, depending on the boiler power. Each boiler is subjected to a meticulous pressure test aimed at monitoring the combustion processes.

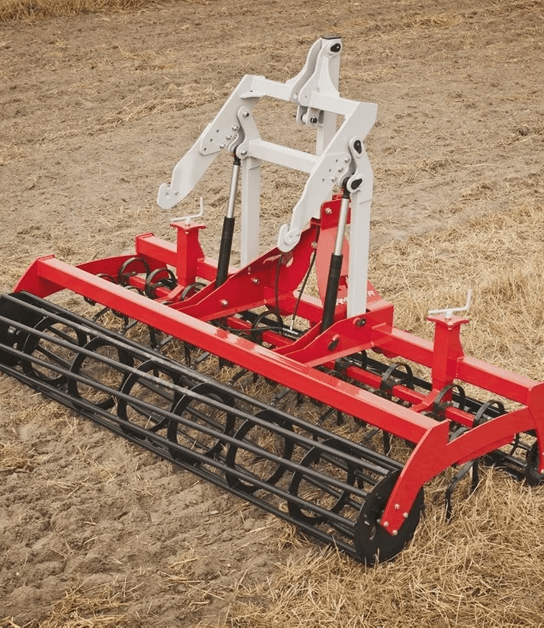

Boilers with a feeder

For heating single-family and multi-family houses, as well as public utility buildings.

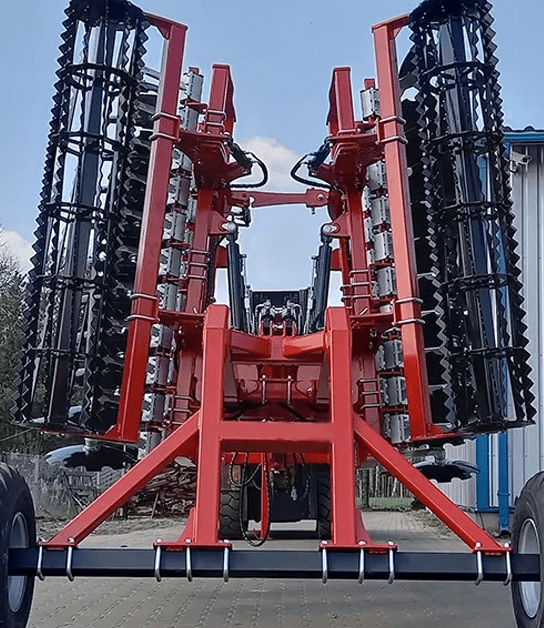

Coal boilers

For supplying central heating and domestic hot water (DHW) installations.

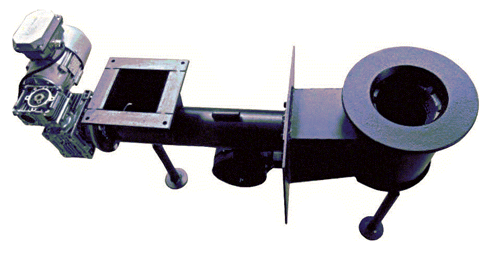

Pellet boilers

With a fuel bin and an automatic feeder, it is designed to supply central heating installations

- saving + 40% compared to a standard boiler

- a smokeless ecological combustion process

- free choice of boiler operation

- mechanical regulation of the air draft

- convenient loading (loading chamber door)

- reduced heat losses (anti-corrosion sheets)

- two operating modes (automatic and traditional)

- saving fuel materials

- ecological combustion process

- for non-wood biomass

- screw conveyor

- lighter can be added

- automatic work management

- designed by professionals

- cooperation with the room regulator

- for pellets

- modulating the power

- firing up system

Our partnersPartners and customers