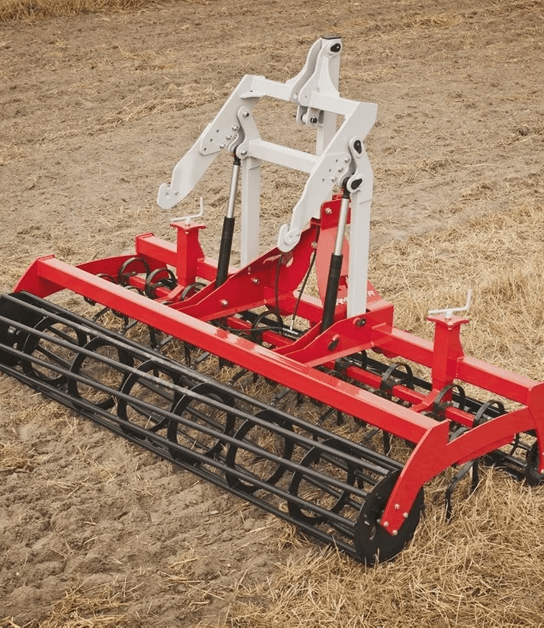

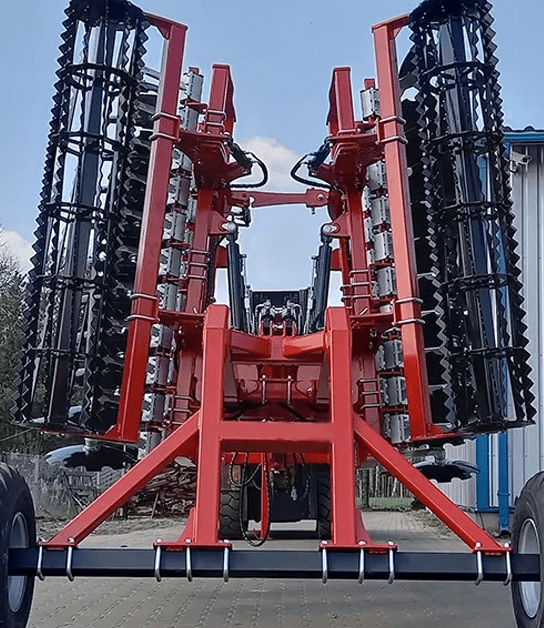

Disc harrows they are used to perform some of the heaviest work on the farm, namely cutting the top layer of the soil and turning it over. Thanks to this, the soil is thoroughly mixed and loosened, creating good conditions for plant development. Which is why plates occupy a high place in the ranking of agricultural machines. Disc harrow it is a kind of investment that will pay off during its operation. Check how to properly care for it so that it retains its effectiveness for a long period of time, without any major failures.

- Proper use of the disc harrow

- Maintenance of the plate in the season

- Choose parts for the disc harrow from trusted manufacturers

Proper use of the disc harrow

Disc harrow is an advanced agricultural machine that requires appropriate knowledge about its use in post-harvest and pre-sowing cultivation. It shouldn't be used harrows for purposes other than those approved by the manufacturer. Because this can result in failure not only of parts, but of the entire equipment. In addition, you cannot make arbitrary changes to its design, because incompatible elements lead, among other things, to malfunction plates.

Proper preparation of the machine for work is just as important as its thorough cleaning of soil and plant debris after each treatment. This is due to the fact that plant residues wind up in the bearing points of the discs and the tillage roller, hindering their movement. As a consequence, during the next use, more of them are collected, even leading to the complete blocking of the moving parts of the machine during operation. However, after the end of the season, it is necessary to repair damage to the paint coating and protect the remaining elements against corrosion.

Maintenance of the plate in the season

Even with proper use disc harrow there is wear and damage to the working elements, just like with any other agricultural machine. Therefore, it is very important to check the technical condition of individual parts that are characterized by the highest failure rate. Plates, bearings, bearing and spacer sleeves, bushings, bushing frames, caps and nuts deserve such systematic control. By controlling their technical condition, we reduce the risk of other failures during the gradual deepening of damage affecting the quality of work.

In addition, keep the main elements in mind disc harrow such as the frame, axle and hubs, because although they are the least likely to fail, they need proper maintenance in the form of grease lubrication. This allows you to effectively eliminate incorrect friction in the moving components of the machine and thus increase their durability.

Choose parts for the disc harrow from trusted manufacturers

W disc weapons wear parts often occur, so it's a good idea to have a few spare parts in your workshop to be able to replace them immediately. In this way, we will not have to stop working in the field and wait for the delivery of new components.

If there is a failure of any of the basic elements that we do not have in stock. Don't worry. Currently, manufacturers of agricultural machinery guarantee really fast delivery of spare parts orders. The second issue, however, is their quality, namely, many people pay mainly attention to the price, which often leads to the purchase of poor quality substitutes that break down after just a few trips.

For this reason, we recommend looking for parts in the assortment from proven manufacturers, where they also offer this type of replacements disc harrows at an attractive price. As a consequence, you will actually get rid of the problem and you will have peace of mind with the replacement for some time. We can recommend the company with full confidence Brastalwhich today enjoys great trust among farmers themselves.

Related entries:

- Various applications of the disc harrow in agriculture

Let's take a look at the various applications and countless benefits that the disc harrow brings to farms.... - Cultivation on heavy soils - the choice between a disc harrow and a plow

Growing on heavy soils requires precise selection of implements. Both the plow and the disc harrow have... - What is a disc harrow?

Currently, modern agricultural machines are used to fertilize the soil, such as disc harrows, which have... - Fertilization and tillage - which agricultural machines to choose?

Learn the functions of agricultural machines used in fertilization and cultivation processes, such as water tankers, manure spreaders,... - Agricultural machinery that eliminates the need for a plow

The disc harrow and tillage unit are examples of agricultural machines used in minimal tillage replacing the traditional...