Choosing the right one disc harrow is crucial for the efficiency of agricultural work. It is worth paying attention to several important factors that will help you make the right decision. In this article, we will discuss what you should pay attention to when choosing platesto meet the needs of the farm and ensure optimal results of work in the field.

- Soil type

- Working width

- Plate design

- Working depth adjustment

- Additional options and equipment

- The importance of durability and reliability

Soil type

The first factor to consider when choosing disc harrow, is the type of soil on which it will be used. Light and sandy soils require different treatment than heavy and clay soils. Harrows with smaller discs may be sufficient for light soils, while heavier soils may require a machine with larger, stronger discs - capable of penetrating deeper and mixing the soil better.

Working width

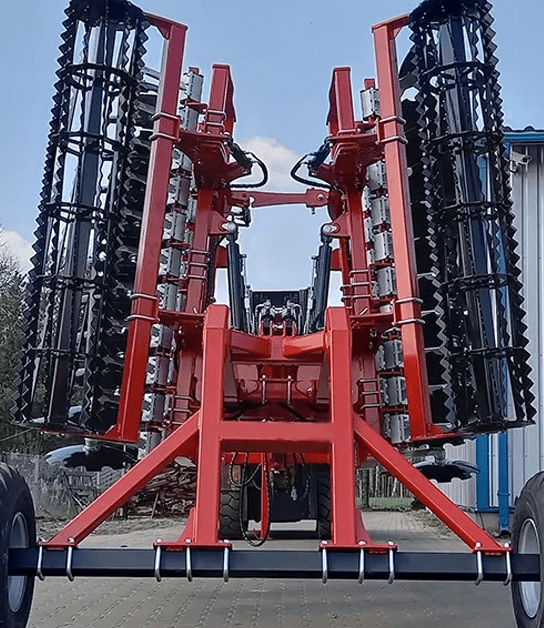

Another important factor is the working width. You should choose a model that will be appropriate for the size of the field and the power of the tractor. Too narrow disc harrow it may require more passes, increasing costs and operating time, while if it is too wide it may be difficult to maneuver in narrow fields.

Plate design

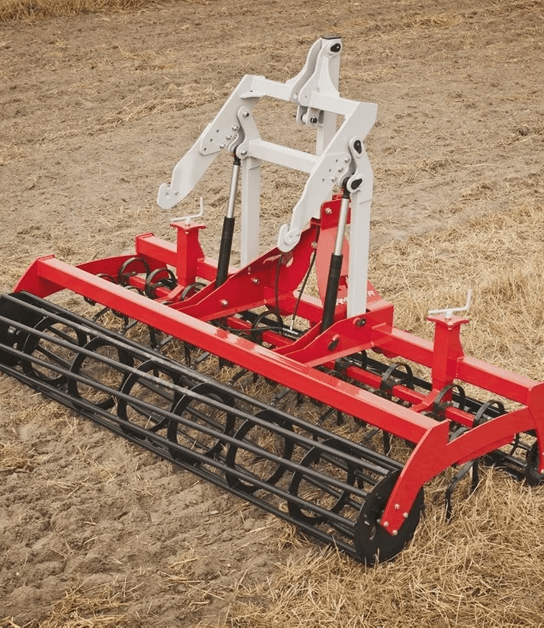

The design of the discs has a significant impact on work efficiency disc harrow. It is important that the plates are solidly made and have adequate durability for field conditions. Additionally, it is worth paying attention to their angle of inclination and diameter, which affects the working depth and effectiveness of shredding plant residues.

Working depth adjustment

The ability to adjust the working depth is extremely important, especially in the context of the diversity of soil conditions. Plate rolls offering easy and precise adjustment, they allow you to adjust the plowing depth to current needs, which translates into better work efficiency and optimization of crop growth.

Additional options and equipment

It is also worth paying attention to additional options and equipment of the harrow that may affect its functionality and efficiency. These include, for example, pressure roller systems that help ensure even soil compaction after processing, and contamination protection systems that reduce the risk of damage to the machine.

The importance of durability and reliability

choosing disc harrow, the issue of durability and reliability cannot be ignored. High-quality equipment made of durable materials will serve for years, minimizing the need for frequent repairs and replacement of parts. It is therefore worth investing in machines from renowned manufacturers such as BRASTAL, which offers warranty and service support to its customers.

Related entries:

- Cultivation on heavy soils - the choice between a disc harrow and a plow

Growing on heavy soils requires precise selection of implements. Both the plow and the disc harrow have... - How to recognize a reputable manufacturer of agricultural machinery?

The choice of agricultural machinery from a reputable manufacturer has a significant impact on the efficiency of the farm. Check what... - Various applications of the disc harrow in agriculture

Let's take a look at the various applications and countless benefits that the disc harrow brings to farms.... - Increased interest in disc harrows in agriculture

Find out what features make the disc harrow an irreplaceable tool for farmers today... - Key factors determining the choice of a shaft for an agricultural machine

Choosing the right packer is critical to field efficiency and final results. Explore the available...