Accurately sowing seeds at regular intervals over a large area is almost impossible without the appropriate equipment. Exactly that seeders they allow for precise placement of the seed material in the soil and its proper coverage. Hence, they have become one of the key tools in agriculture. There are two main types seeders: mechanical i pneumatic, with the latter solution gaining more and more popularity. Let's consider why.

- Construction and mechanism of operation of pneumatic seeders

- Evolution of the seed box

- Benefits of large box capacity

- Seed Loading Challenges

- Unexpected reliability

- The issue of sowing precision

Construction and mechanism of operation of pneumatic seeders

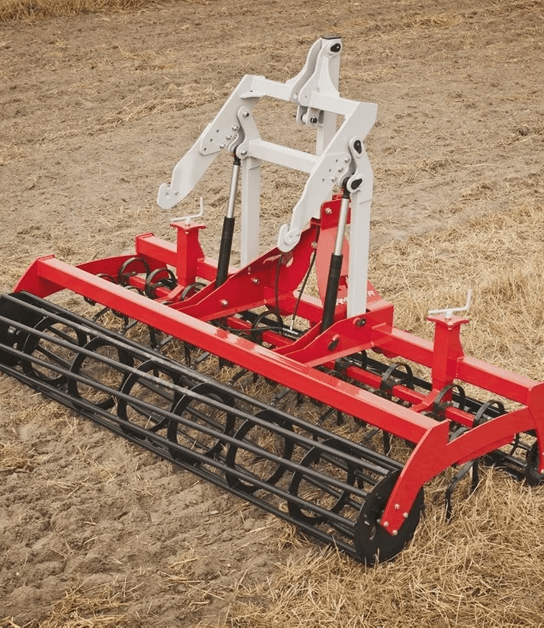

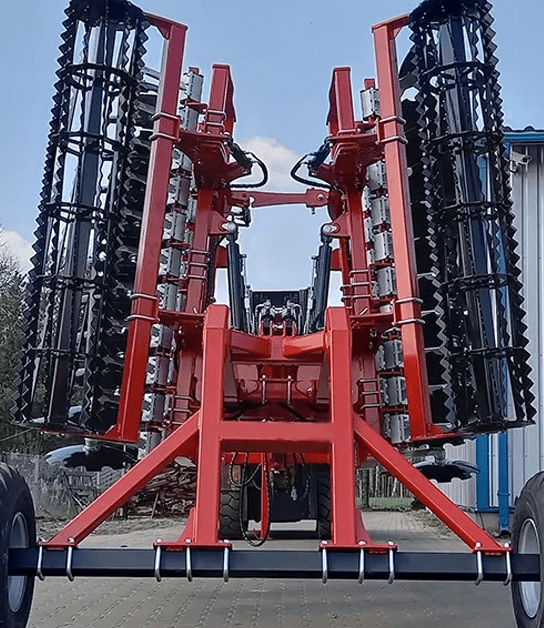

Pneumatic seeders are characterized by an advanced mechanism based on two key modes of operation: vacuum and overpressure. Thanks to this, they guarantee exceptionally effective seed transport via precise distribution heads. These heads use a generated air stream to direct the seeds into the seeding tubes, which effectively places them into grooves in the soil. Individual grooves are previously created using double-disc coulters, ensuring even distribution of seeds.

One of the innovative features of this type seeders is a gravity-independent seed box that can be placed in any location in relation to the coulters, thus optimizing the efficiency of the entire sowing process.

Evolution of the seed box

advanced pneumatic seed drills They have a well-thought-out design of the seed box. Its narrower design compared to standard models effectively eliminates the problem of seeds accumulating on the sides, so farmers do not have to stop work to control the content or move the seeds.

Moreover, the practical location of the box on the machine allows loading a much larger amount of seeds than in the case of mechanical seed drills. Despite the increased capacity, the tractor does not experience additional load, which is the result of its close position in relation to the rear axle of the vehicle.

Benefits of large box capacity

The advantage of a larger box is the possibility of sowing in a large area without the need to constantly replenish the seeds. As a result, farmers do not have to stop as often to refill the box. This, in turn, reduces the number of heavy trips agricultural machinery around the field, shortening working time and lowering fuel consumption.

Regardless of the number of seeds we want to sow - whether more or less - pneumatic seeder he handles it perfectly.

Seed Loading Challenges

However, the large capacity of seed hoppers is not without its drawbacks. Loading large amounts of seed manually can be not only inconvenient, but also time-consuming. In such a situation, it is worth using agricultural machine equipped with a loader. Thanks to it, we will save both time and manpower, making the entire process easier.

Unexpected reliability

Although it might seem that pneumatic seed drills are more prone to failure, it turns out that they are much more reliable compared to their mechanical counterparts. This is the result of the use of durable distribution heads and efficient fan drives, thanks to which work with seeder is stable even in difficult conditions.

Of course, like any other agricultural machine may require replacement of some components as they wear, but such maintenance is standard industry practice.

The issue of sowing precision

Despite many advantages pneumatic seed drills, one of their weaker points is the precision of sowing. Shocks and the specific operation of the distribution head can lead to slight inhomogeneities in seed distribution. Nevertheless, these differences are small and do not significantly affect the results of cultivation.

Related entries:

- Fertilization and tillage - which agricultural machines to choose?

Learn the functions of agricultural machines used in fertilization and cultivation processes, such as water tankers, manure spreaders,... - Appropriate care of grasslands

To ensure optimal productivity of grasslands, specialized agrotechnical treatments are necessary, including dragging and... - Why should you remember about the date of sowing catch crops?

Probably everyone is aware that the quality and size of the crop depends on the fertility of the soil in... - Buying an agricultural machine - what should you pay attention to?

If you are looking for machines online, pay attention to the offers of manufacturers who have been... - Subsoiling - a key process in soil cultivation that is worth knowing

Subsoiling is an important process in soil cultivation that is often underestimated, but has a huge impact...